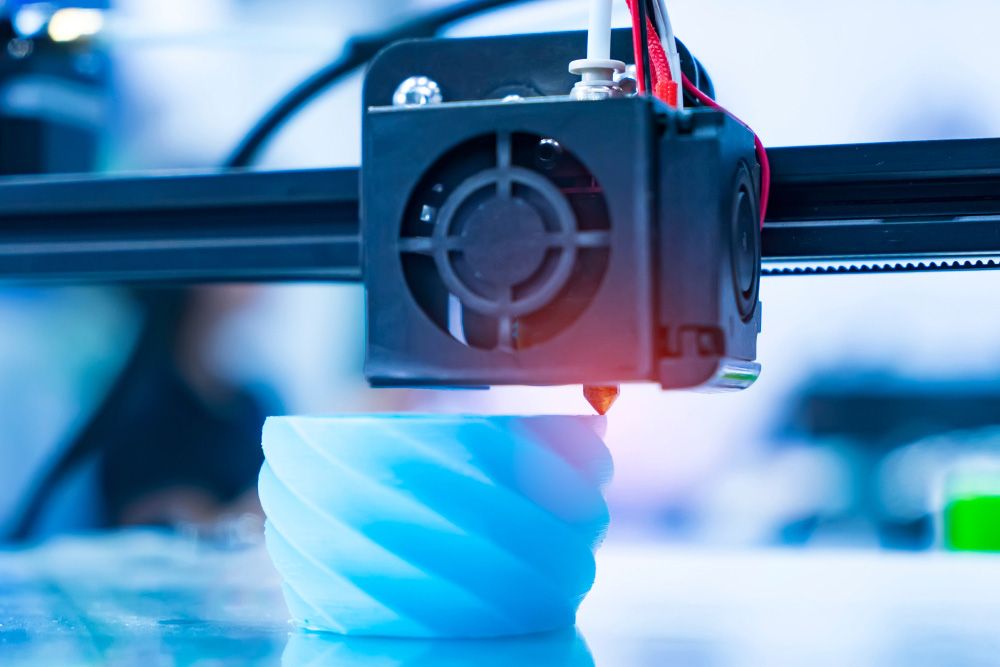

The 3D printing technology has become an essential part of many industries, as it has improved how certain products and parts are designed and manufactured. It is a handy option even for individuals whose professions revolve around design. Here, with the help of a 3D printer, a physical object is created from a digital design file. While this may sound straightforward, there’s more to the process and initial setup, which beginners might benefit from understanding.

Tips for choosing a 3D printer

When considering starting 3D printing, investing in a 3D printer is a major step. Here, one must assess their needs to choose the right machine. For instance, if one is starting with 3D printing as a hobby, simple 3D printers might do the job. On the contrary, professional designers may require sophisticated printers that make precise, functional parts. Based on their needs, one must also consider a few other key aspects.

Consider print quality

A 3D printer creates an object by laying down thin layers of material, which can be liquid or powdered plastic, metal, or cement, and then fusing these layers. The quality of the output is determined by how thin each layer is. The thinner the layer, the smoother and more detailed the result.

Check build volume

This parameter determines the maximum size of the objects that can be printed. So, beginners choosing a 3D printer must first consider the dimensions of the intended design projects and then pick a printer that can deliver the desired build volume.

Assess print materials and compatibility

Printers are designed to work with specific filament types, such as ABS, PLA, PETG, and TPU. Filaments are thermoplastic materials used to create 3D objects. Each type has unique properties in terms of their strength, flexibility, and heat resistance. To choose the best 3D printers, one must check the materials that the chosen machine can work with, and then see if the compatible materials align with the project requirements.

Examine printer speed and resolution

These specs can help one determine if a 3D printer will deliver good results. A fast printer might help one save time, but offer poor render quality. On the other hand, a 3D printer offering top-notch resolution may work slowly and create better finished products. To ensure one chooses the right printer, one must choose an option that offers good resolution in a reasonable time frame.

Review printer software

Examining the software can help one determine if the printer can promise long-term utility. While some 3D printer manufacturers provide their own software with limited compatibility, others offer printers compatible with open-source platforms. A good software system offers handy features and integrates with other platforms.

Assess connectivity

This is also a key factor to consider. Some 3D printers may need a direct connection to a computer. Others can print from an SD card or Wi-Fi.

Consider cost

3D printers can vary in price based on various factors, including their purpose.

Between $100 to $400

These 3D printers are suitable for beginners who want to get the hang of 3D printing. Most low-cost options come with step-by-step instruction kits and tutorials to help new users put the device together, providing a fun, hands-on introduction to 3D printing. That said, these low-cost 3D printers may lead to additional expenses if users need to upgrade, modify, or repair them in the future.

Between $400 and $1,000

An upgrade from low-cost printers, these mid-range hobbyist 3D printers are designed for those who enjoy learning, watching tutorials, and fine-tuning settings to get the best quality 3D results.

Between $1,000 and $5,000

Experienced 3D printing enthusiasts should explore printers in this price range. These can be perfect for independent designers or schools that want a professional-like setup. Printers in this price range tend to have additional features like covers that make the machines safer. These features also enable proper material utilization and better-quality prints. These printers also offer features similar to those of industrial-use printers, giving users advanced printing experiences. That said, these printers are not designed for industrial use.

Premium printers

Sophisticated printers, designed for bulk 3D printing and industries, can range from $5,000 to over $10,000. So, beginners could avoid spending on such devices, at least until they get the hang of 3D printing.

Steps to get started with 3D printing

Once one chooses the right 3D printing device, one can start the process in a few steps.

- The first step in 3D printing is creating the design with the help of software like CAD. Beginners can learn about the software by signing up for a CAD course or watching online tutorials. Alternatively, beginners can use online resources to source free designs and speed up the process.

- Once the design is ready, export or download the STL file. This format stores the information regarding the conceptual 3D object.

- Now, one must pick from various available 3D printing materials based on the properties of the desired object.

- Next, choose the different parameters of the object and the printing process, including the size and placement of the print.

- Import the STL file into a slicing software, like BCN3D Cura. The software converts the information from the STL file into a Gcode, which contains a specific set of instructions for the printer.

- Once the command is sent, the printer will create the object layer by layer. The project will be completed in minutes or hours based on the object size, printer, and materials used. Additionally, based on the final product, there might be a few additional steps once the printing is done, such as painting and brushing off.